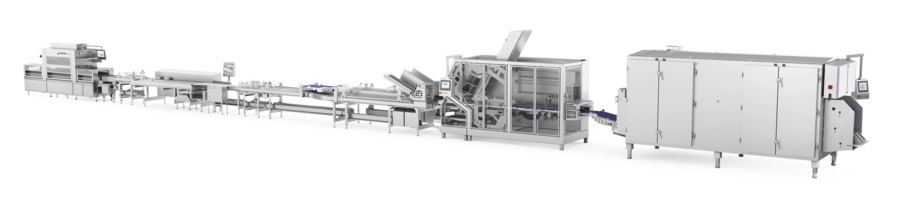

GMS 1000

IMPRESSIVE TECHNOLOGY

-

Maximal product quality during cutting, shaping, and portioning

-

Highest flexibility with varying sizes of raw material

-

Increased yield through waste-less portioning

-

Giveaway reduction through high weight accuracy and perfect slicing

-

Automatable through shingle portions or single-slice placement

-

Intuitive user interface for operators and cleaning staff