NO MEAT? WE LOVE THAT AS WELL

Those who know how to portion meat are, of course, also able to cut other foods. Our love makes no distinction. Whether plant-based meat, halloumi, corn on the cob, mussels or meat loaf – the portioning systems from TVI are true multi-talents and open to every taste. Give it a try!

Cubes

GMS 520

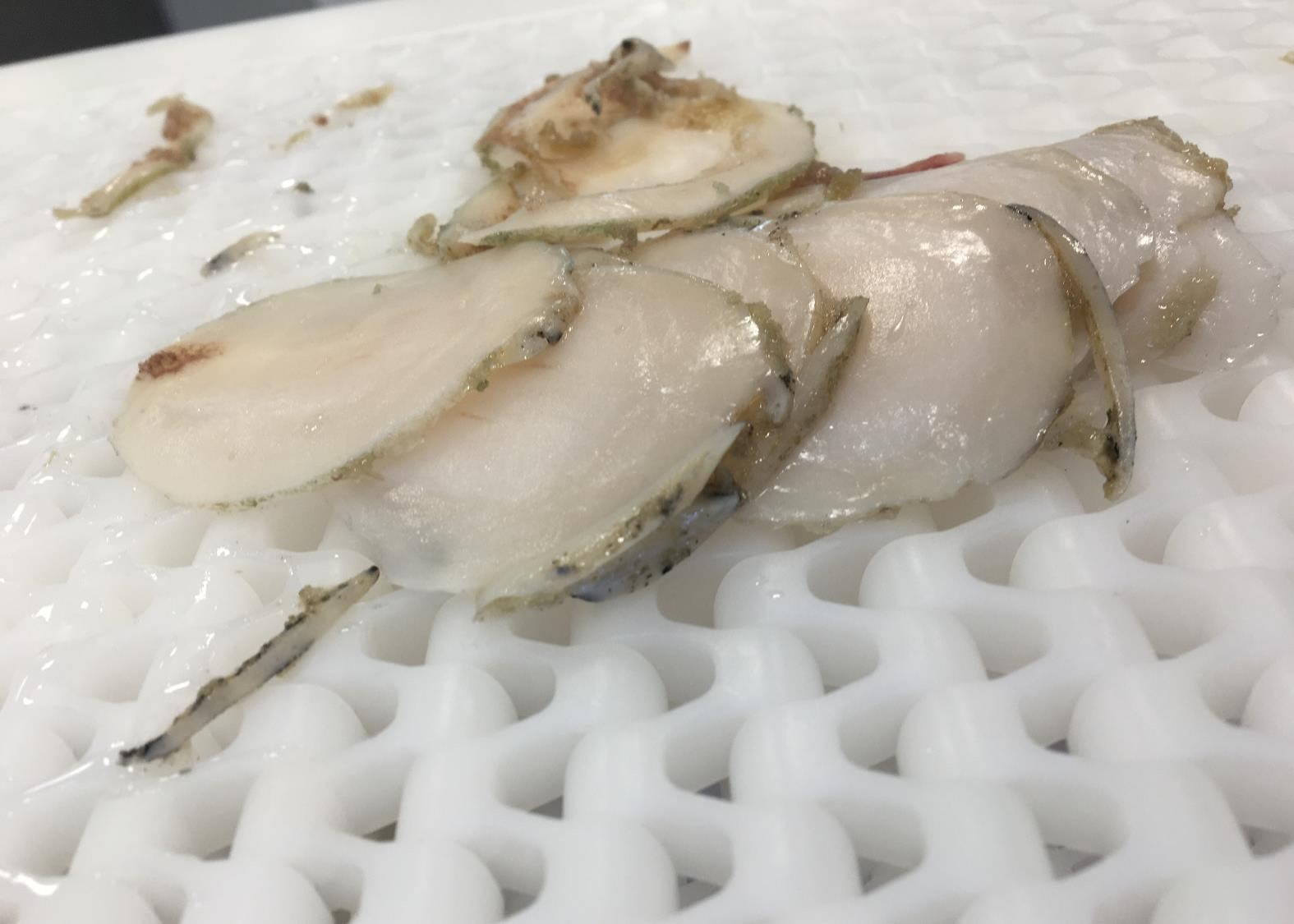

Abalones

GMS 520

Beef Jerky

GMS 520

Forming set NKR009; press piston & forming hole R3 equipped with a dicing grid; boneless knife KN300134; portioning on thickness of the meat strips of 5 mm.

Although meat is injected, cut per-fect, nice meat strips with an uniform & exact thickness of 5 mm; achieve even positioning on the discharge conveyor in portions, without the strips sticking together.

Even meat strips with a perfect cut-ting edge; target slice thickness of 5 mm. Design a custom-made bigger for-ming hole on both sides of the for-ming rings to be able to cut bigger peaces of meat and fi ll the forming holes faster.

Halloumi

GMS 520

Cavity D90 / R3a, 3 rings, knife 134, portioning on target slice weight of 50 g / 33 g, packages 4 x 50 / 6 x 33 g

Cut perfect slices on target weight and achieve nicely shingeled portions despite soft texture; handling of the different shapes of the product: oval chili burgers and natural squares; find out perfect cavities and cutting temperature

Accurate weight of the slices, clear cuts. For the square product, new cavities of 90 x 40/50 cm will be necessary. A thinner knife would also be recom-mended.

Injected Meat 40%

GMS 1600

3D boneless forming set 180; 210° knife; portioning on target weight of 160 g & 200 g; single steaks

Find out if 3D pressing and portioning of 40 % injected meat is possible; identify optimum cutting temperature & contact pressure; cut even slices (weight, shape & thickness); achieve uniform positioning on the discharge conveyor; optical & haptic inspection of the slices; avoid leaking of meat juices

Clear cuts, slices perfectly even, uniform positioning. Tempering takes much lon-ger due to high salt content. Meat was vacuum-packed, un-packed and weighed again after 3 days. Weight loss averaged 4 g, only.

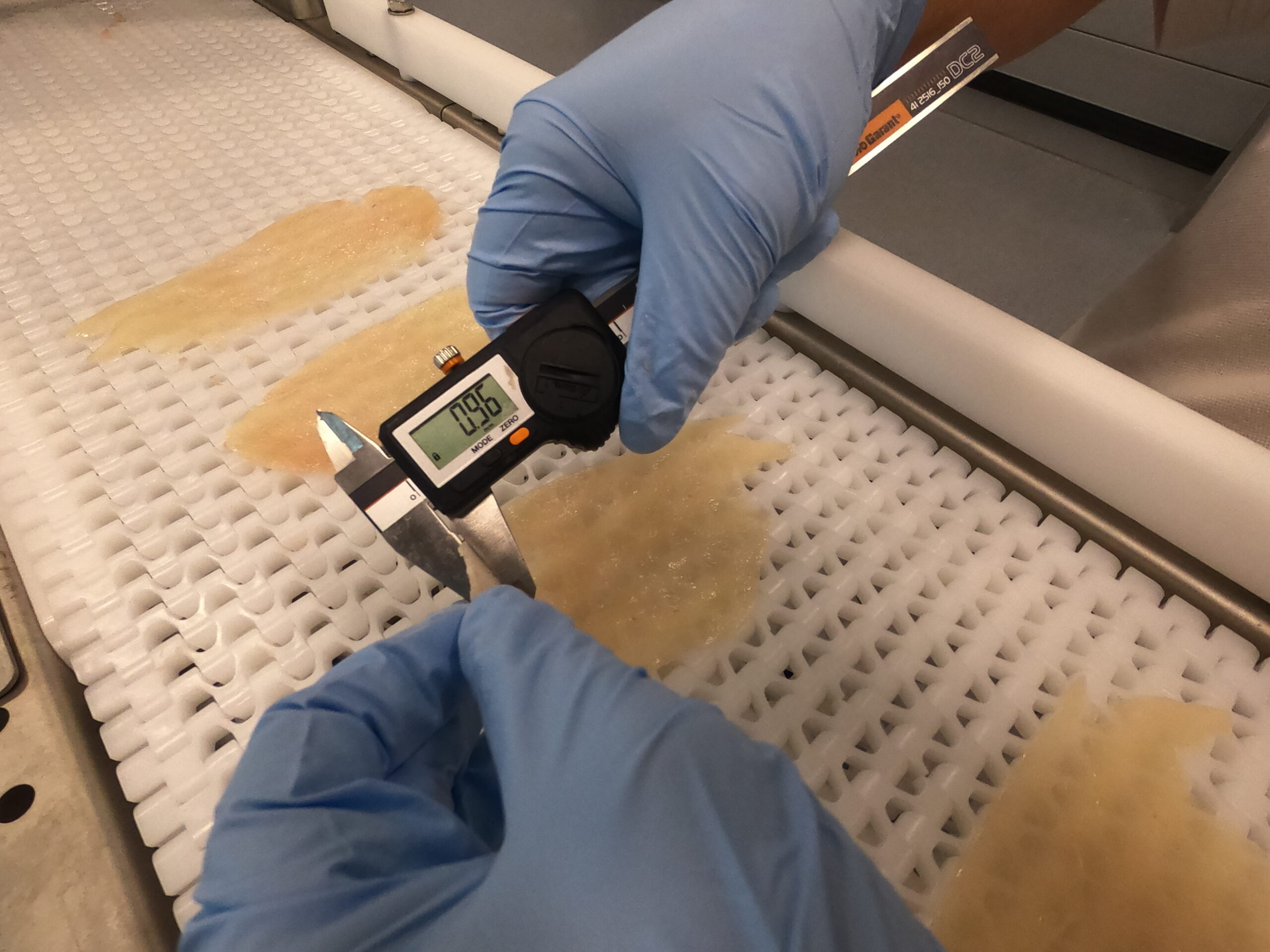

Thin Chicken

GMS 520

Mould set NKR301; punch N36; boneless knife 134; portioning on slice thickness of 3 mm and 5 mm.

Find out the perfect temperature for the best cutting result, as chicken tears quickly; cut perfect, nice, thin slices without tearing; achieve uniform positioning on the discharge conveyor for single slices as well as for seven-piece shingles; high yield.

Even slices with a perfect cutting edge; precise shingling; target weight from 26 to 28 g / slice.