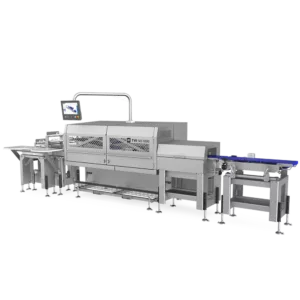

TDS 300

IMPRESSIVE TECHNOLOGY

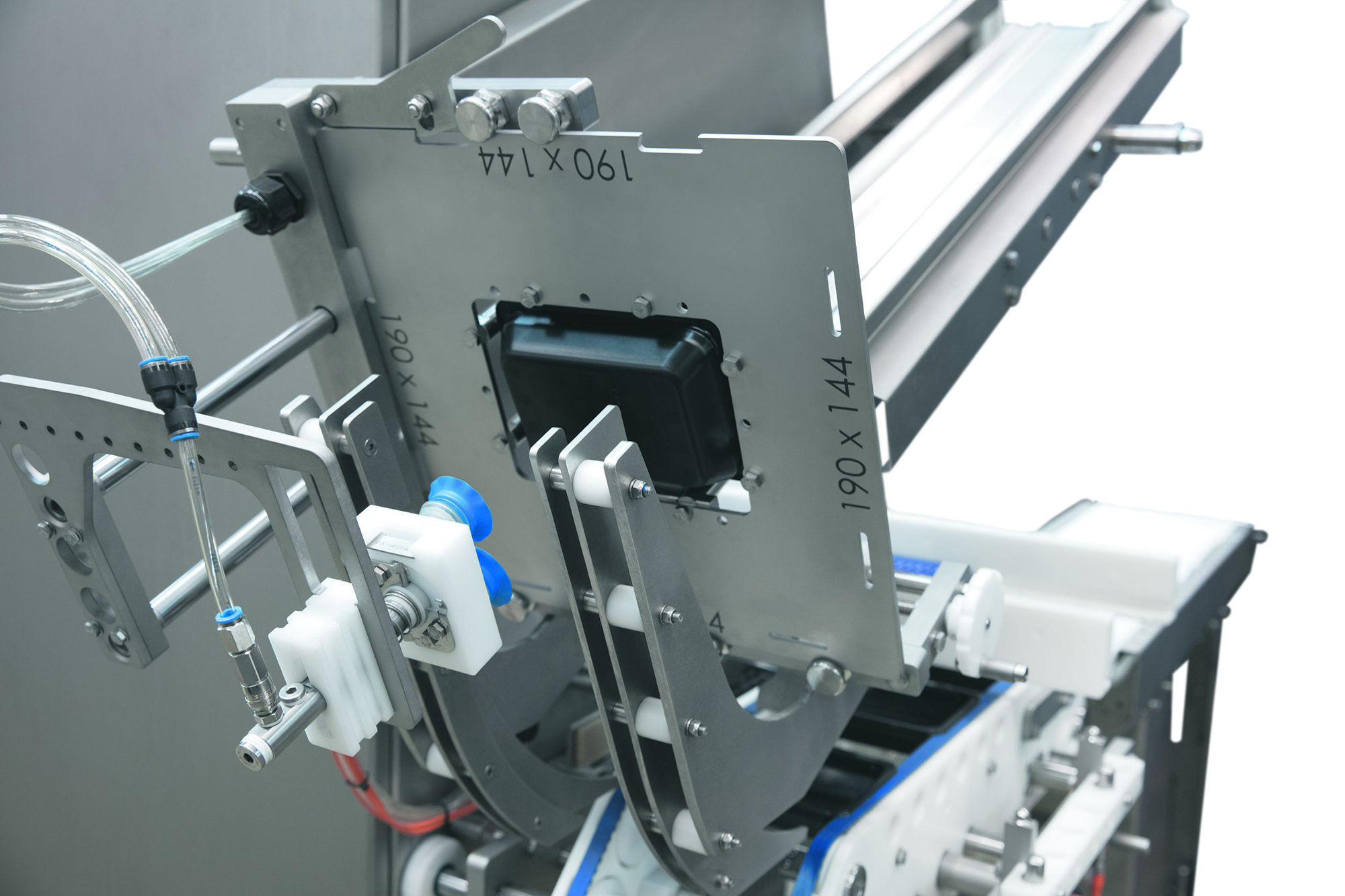

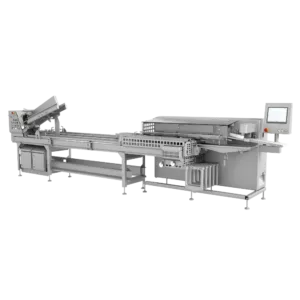

The TDS 300 separates trays of various formats and types (including paperboards and foam trays) and feeds them to a downstream system at a desired cycle time. Once the desired tray mold and the correct vacuum suction cup are installed, the operator can fill the tray buffer with trays of the desired format. At the lower end of the tray buffer, there is a tray mask that holds the lower portion of the tray stack in the correct position for suction. When the TDS 300 is activated, the vacuum suction cup attaches to the bottom tray of the tray buffer and pulls it out in a backward motion from the tray mask. At the lowest position, the vacuum suction cup releases the separated tray, which exits the TDS 300 through a tray slide to the downstream system.