GFW 3600

IMPRESSIVE TECHNOLOGY

- Very high level of personnel efficiency due to reduction in manual work

- Simplification of the manual processes; this means simple training of new staff

- Consistent grill stick quality

- Flexibility in skewer length

- High level of productivity thanks to full automation of part processes (skewer separation and transport, winding and placement)

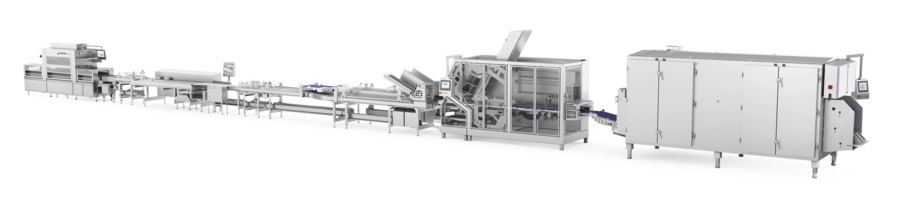

- Modular integration in TVI line systems is possible

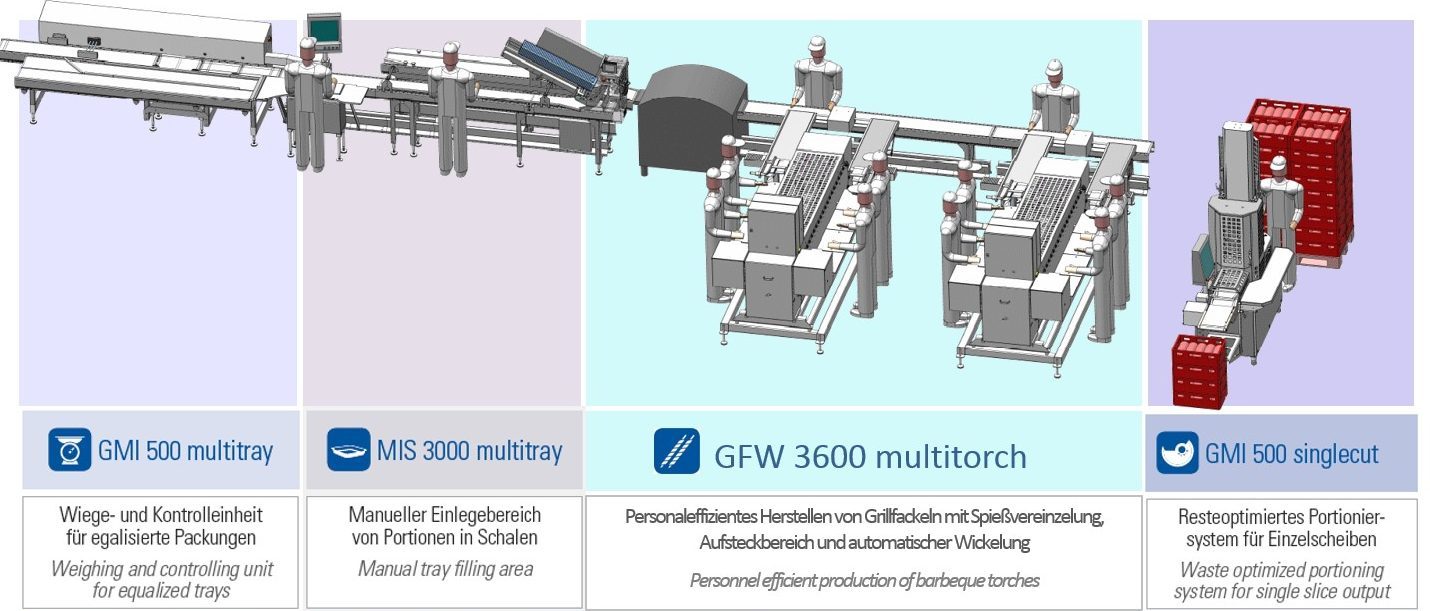

This production line comprises the following TVI modules:

GMS 500/520 singlecut

The TVI GMS 500/520 singlecut portions all forms and consistencies of red meat into any size of portion and always with the optimum weight and trim.

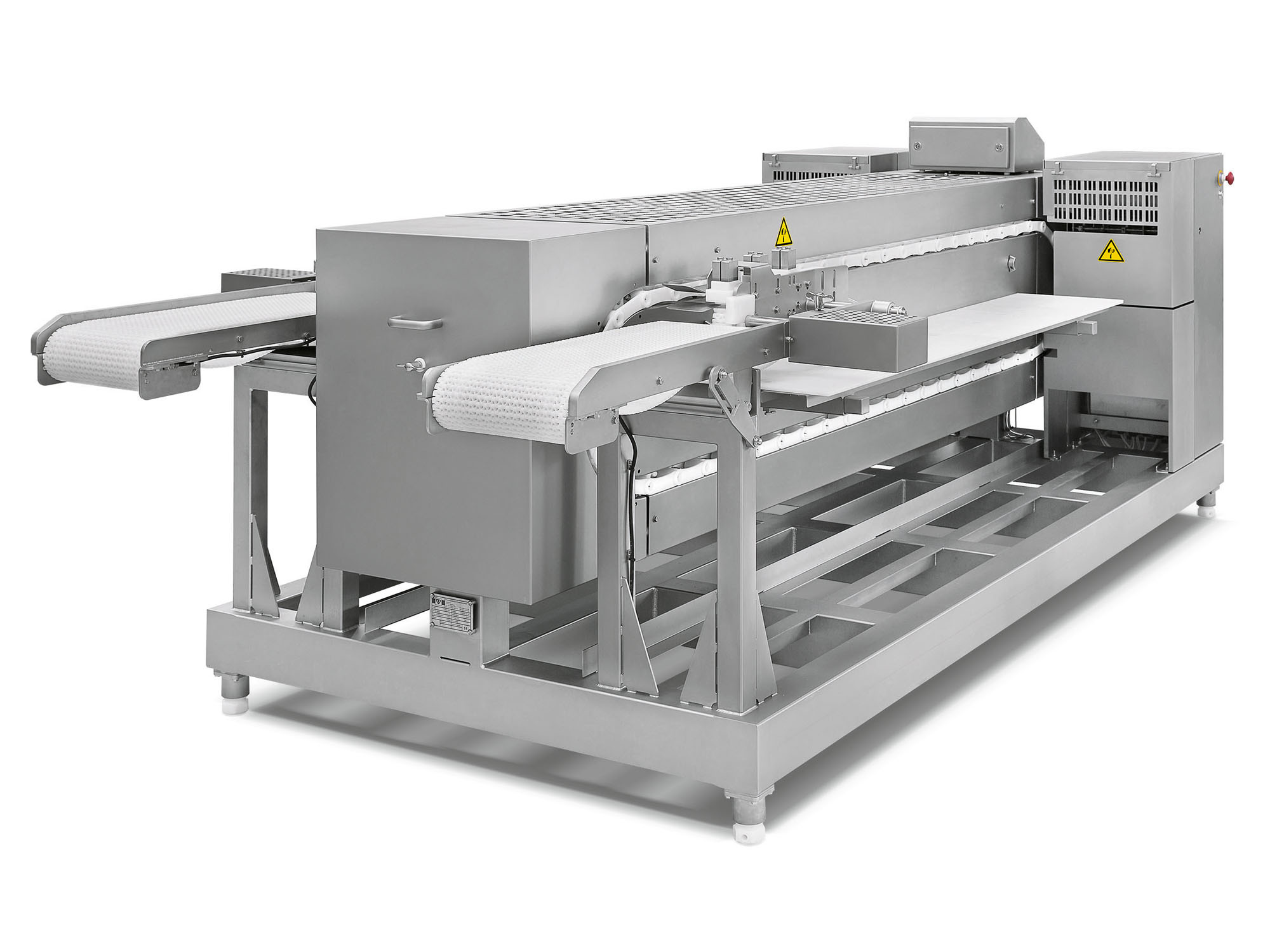

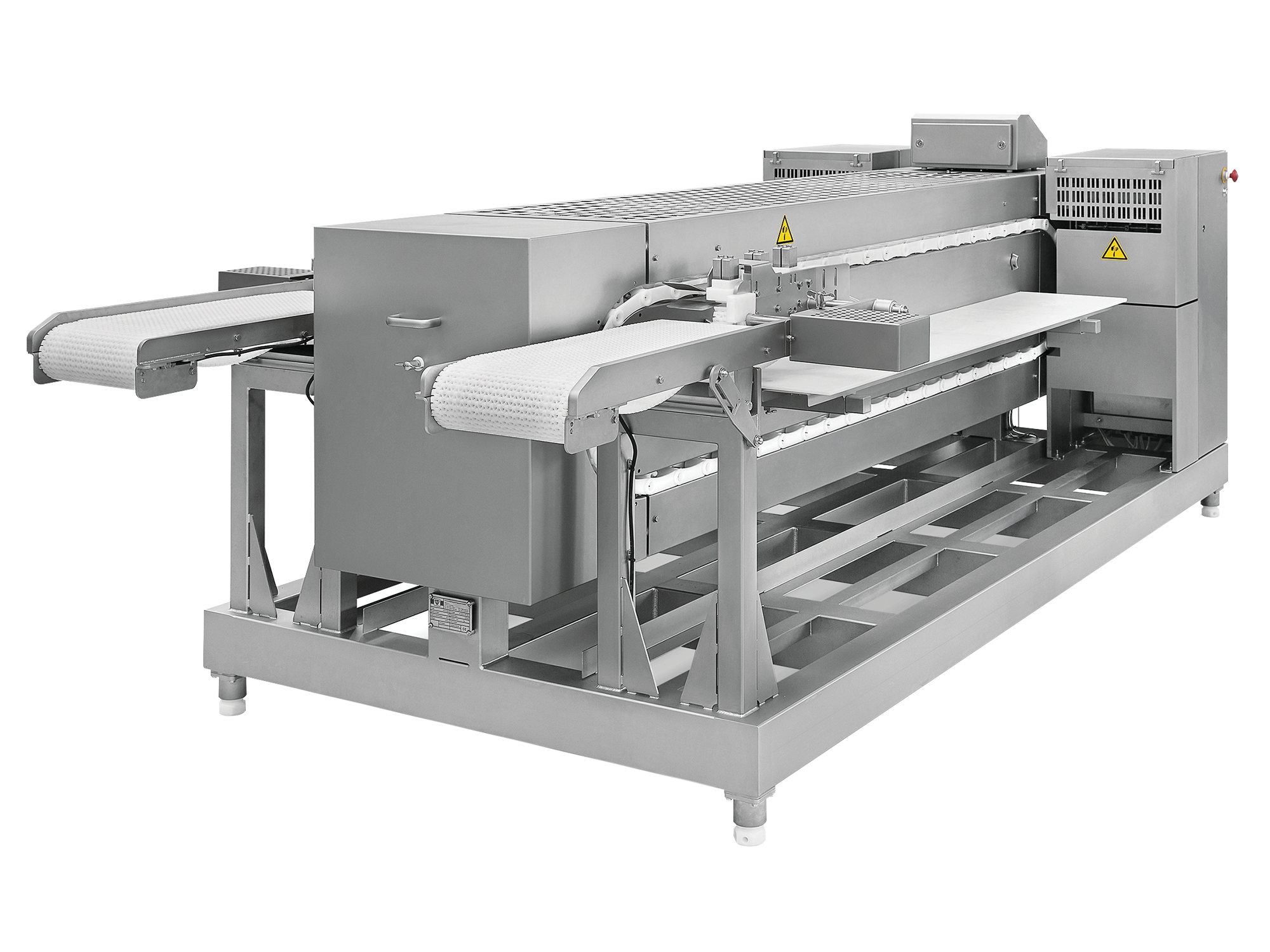

GFW 3600 multitorch

Flexible barbecue skewer machine for highest product quality with the lowest manpower requirements.

MIS 3000 multitray

Area for manual placement of portions into trays.

GMI 500 multitray

Weight and inspection unit for equal packs.